Procedure and solution:

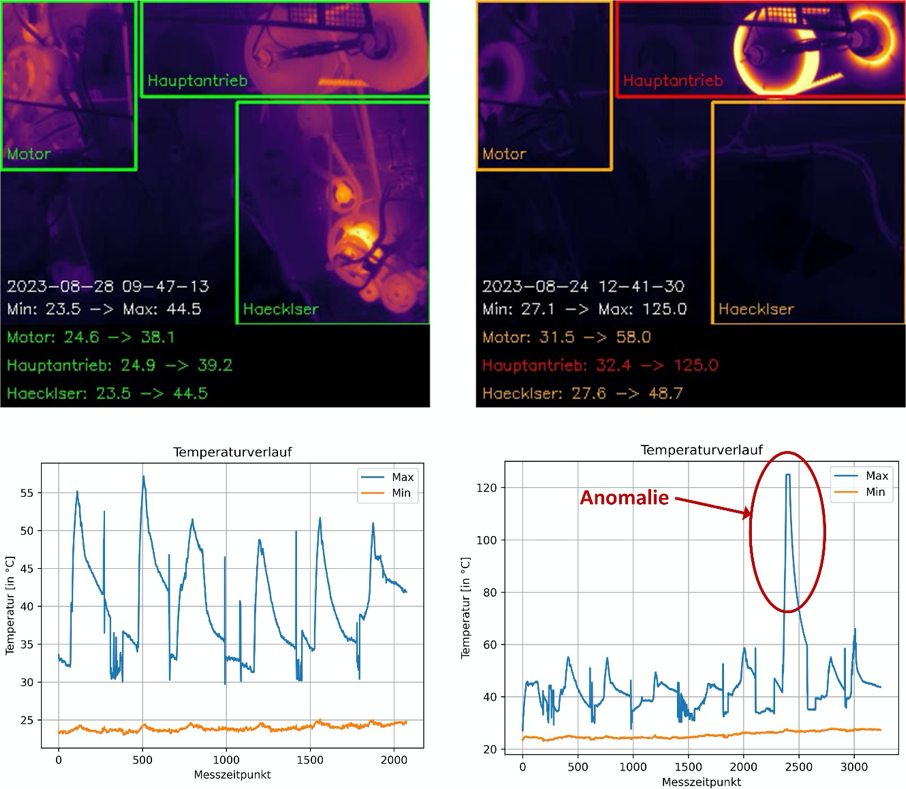

As part of the „Datenfabrik.NRW“ project, the process of the described functional test was (partially) automated using a technical system. This was intended to make the testing process reliable, increase the resulting product quality and support the employees in the test cabin. In a first step, a test concept was developed for this purpose, which provides for thermal imaging camera-based recording of one side of the combine harvester combined with automated image evaluation. The test cabin was then equipped with a specific thermal imaging camera in order to quantitatively record the heat development using a technical system. In preparation for the automated implementation of the test task, test images were then taken over several weeks in order to determine threshold values for anomalies in the data. Finally, an application for the automatic detection of faulty components was implemented and the image processing system was integrated into the existing inspection process at CLAAS.

Customer benefits:

- Increase in product quality

- Fewer returns

- Support for employees

What the Datenfabrik.NRW lighthouse factories have to say about the work package:

By recording and checking the heat development of various rotating components, a possible deviation can be detected more specifically, reliably and quickly.

“Our employees are relieved by the thermal image-based anomaly detection in the inspection process. A subjectively perceived heat development had to be identified and checked in a time-consuming process. Anomaly detection allows us to see directly and precisely where the heat development exceeds a threshold value and which component is responsible for this.”

In addition to simplifying the testing process, the objective inspection can also achieve a higher rate of fault detection. In the future, it may be possible to adjust this threshold value more precisely using data from the market. This may make it possible to identify defects that are not currently perceived as such by humans.

Industrial Automation branch INA

Industrial Automation branch INA